Surface mount technology forms the backbone in the manufacturing of high-density electronics. This process involves mounting electronic components directly onto the surface of a printed circuit board (PCB). The inherent advantages of SMT, such as its small footprint, high component density, and cost-effectiveness, make it suitable for modern electronics needing miniaturization and increased functionality.

- Robotic SMT systems have revolutionized the manufacturing process by enabling high-speed placement of components with exceptional accuracy.

- Wave soldering, a critical step in SMT, ensures robust electrical connections between the components and PCB.

- Testing procedures are crucial for guarantee the reliability and functionality of high-density electronics manufactured using SMT.

The ongoing advancements in SMT continue to drive innovation in the electronics industry, enabling the design of increasingly complex and sophisticated devices.

Automated Assembly Lines: Streamlining Electronics Production

Within the dynamic electronics sector, productivity is paramount. Automated assembly lines have emerged as a transformative force, revolutionizing how/the manner in which/the process of electronics are produced/manufactured/created. These sophisticated systems leverage robotic arms and cutting-edge technology/software/tools to execute repetitive tasks with unparalleled precision/accuracy/exactness. By eliminating/reducing/minimizing manual labor, automated assembly lines dramatically enhance throughput/output/production capacity, leading to faster/quicker/rapid turnaround times and reduced/lowered/diminished production costs.

- Moreover, automation empowers manufacturers to achieve greater consistency and quality/reliability/dependability in their final products.

- Furthermore/Additionally/In addition, automated assembly lines can seamlessly integrate with other aspects of the manufacturing process, such as supply chain management/inventory control/logistics.

- This integration enables real-time monitoring/tracking/observation of production progress and facilitates data-driven decision making.

As the electronics read more industry continues to evolve, automated assembly lines will undoubtedly play an increasingly crucial/significant/vital role in shaping its future.

Printed Circuit Board Manufacturing and Design

Printed circuit boards (PCBs) are the backbone of modern electronics. The method of PCB fabrication involves a series of intricate steps, from engineering the layout to connecting the components.

Designers utilize specialized software to create precise schematics and layouts that dictate the placement of components and the routing of electrical paths. These designs are then transferred to a substrate material, typically epoxy, through various etching techniques.

Subsequent steps involve depositing conductive materials, drilling vias for electrical connections, and placing components onto the board. Testing procedures ensure the functionality and reliability of the final product.

Global Electronics Production Challenges in a Interconnected Market

Navigating the complexities of electronics manufacturing in today's rapidly evolving global market presents substantial challenges for businesses. Procurement of high-quality components from a diverse range of suppliers can be demanding, particularly given fluctuating rates. Additionally, manufacturers face the ongoing pressure to enhance production techniques to decrease costs and maintain competitiveness. Additionally, meeting ever-increasing requirements for product functionality while adhering to stringent quality standards is a vital aspect of prosperity in this competitive landscape.

Sustainable Practices in Electronics Manufacturing

The electronics manufacturing market is constantly evolving, and with it comes an increased emphasis on sustainability. Manufacturers are adopting a variety of methods to decrease their footprint on the planet.

Key initiatives include upcycling electronic waste, conserving energy and water supplies, and acquiring ingredients from ethical providers.

Moreover, manufacturers are committing in advanced technologies to streamline production processes and decrease waste generation. Finally, these green practices not only enhance the planet but also fortify the brand image of electronics manufacturers in the global economy.

Inspection Procedures in Electronics Production

In the intricate world of electronics manufacturing, guaranteeing quality is paramount. A robust framework of testing is critical to eliminate defects and produce reliable products.

From raw materials to the final assembled product, each stage undergoes stringent scrutiny.

Sophisticated testing instruments are employed to inspect a comprehensive range of parameters. This may comprise testing for performance, reliability, longevity, and conformity with industry standards.

Thorough documentation of test outcomes is vital to record quality trends, identify potential issues, and execute corrective actions. By strictly following a comprehensive quality control process, electronics manufacturers can strengthen customer confidence.

Luke Perry Then & Now!

Luke Perry Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Jurnee Smollett Then & Now!

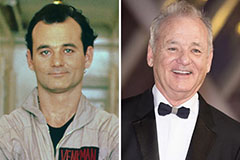

Jurnee Smollett Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!